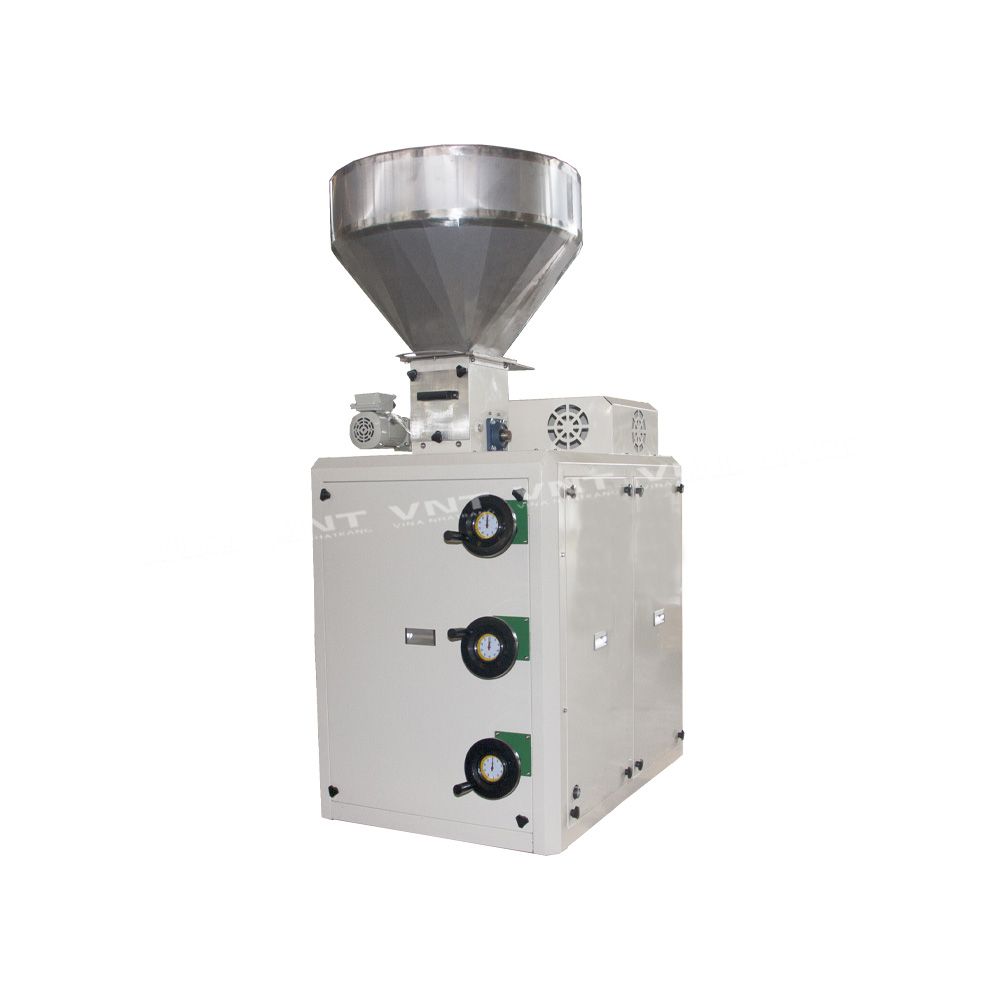

Industrial Coffee Mill Guide: Increase Performance and Quality

In the competitive landscape of coffee production, selecting the right industrial coffee mill plays a pivotal role in enhancing both performance and item top quality. Recognizing the subtleties of different grinder types and essential features-- such as customizable work setups and durable building-- can substantially influence the final taste account of the coffee.

Comprehending Grinder Types

When selecting a commercial coffee mill, comprehending the various types readily available is crucial for optimizing both flavor removal and operational efficiency. The 2 key sorts of grinders are blade mills and burr grinders. Blade grinders make use of sharp blades that slice coffee beans into irregular sizes, resulting in uneven removal and potentially unwanted tastes. While blade grinders are usually a lot more inexpensive and ideal for small-scale operations, they are normally not recommended for industrial usage.

Ultimately, choosing the appropriate kind of grinder is important to preserving quality and performance in coffee manufacturing, making it important for companies to buy top notch burr grinders for ideal results.

Trick Features to Think About

Selecting an industrial coffee mill needs cautious factor to consider of several crucial attributes that can dramatically affect both efficiency and the overall coffee experience. One of the main facets to assess is the grinding system. Burr mills are generally chosen over blade grinders, as they supply a consistent work size, which is important for optimal extraction and taste.

Another important function is the grinder's capability. Depending upon the quantity of coffee you need to procedure, pick a design that can handle your demands without sacrificing rate or quality. In addition, think about the grind setups used. A functional mill with multiple setups allows you to tailor the grind dimension to different developing methods, improving the coffee's taste account.

Review the grinder's sound degree, especially in an active coffee shop or manufacturing setting, where excessive sound can be disruptive. Investing in a mill that stabilizes these features can considerably improve both operational effectiveness and the quality of the coffee offered.

Optimizing Grinding Process

To accomplish the ideal outcomes in coffee prep work, enhancing the grinding process is vital. The work dimension dramatically affects removal, taste, and overall high quality of the brewed coffee.

Furthermore, checking the grinding rate can maximize the procedure. Slower grinding typically generates much less warm, protecting fragile tastes and aromas. Conversely, faster grinding may generate excessive warmth, adversely influencing the coffee's top quality.

Upkeep and Care Tips

Proper maintenance and treatment of commercial coffee grinders are vital for making sure ideal performance and long life. Normal cleaning is the foundation of maintenance; deposit accumulation can impact flavor and grinding performance. It is suggested to clean up the grinder after each use, wiping down the outside and eliminating any coffee grounds from the burrs.

In addition, check the grinding burrs for deterioration. Dull burrs can endanger grind consistency, so they need to be replaced as necessary. Industrial Coffee Grinder. Occasionally adjusting the grinder is additionally important, as this maintains the wanted work size for numerous brewing approaches

Lubrication of moving components must be performed according to the supplier's specs, as this reduces rubbing and prolongs the life why not look here of the tools. It is vital to use food-grade lubricating substances to guarantee safety and security and compliance with wellness policies.

Last but not least, keep the mill in a dry and steady environment to stop corrosion and rust. By sticking to these maintenance and care pointers, operators can improve the efficiency of their industrial coffee grinders while guaranteeing high-grade output and expanded functional life.

Roi Analysis

Examining the roi (ROI) for commercial coffee mills is essential for services looking for to maximize their coffee manufacturing capabilities. An extensive ROI evaluation aids establish the financial practicality of purchasing premium mills, enabling services to consider the first prices versus possible gains.

To perform a thorough ROI evaluation, organizations need to take into consideration numerous vital factors. Initially, analyze the acquisition rate of the mill, consisting of setup and any try this site type of required modifications to existing infrastructure. Next, calculate operational prices, consisting of energy consumption, upkeep expenditures, and labor effectiveness enhancements. High-performance grinders usually bring about minimized grinding time and enhanced throughput, which can considerably enhance performance.

Furthermore, consider the influence on product top quality. Industrial Coffee Grinder. Superior grinders generate a more constant work size, which can boost flavor accounts and client fulfillment, ultimately driving sales. By enhancing the top quality of the end product, companies can warrant higher rates, leading to boosted revenue

Final Thought

In summary, an industrial coffee mill plays a pivotal function in boosting both efficiency and item quality within coffee production. By choosing top quality burr mills geared up with crucial features such as adjustable work setups and resilient building, organizations can guarantee ideal taste removal. Furthermore, routine upkeep is critical for sustaining mill performance and maximizing customer fulfillment. Inevitably, the strategic investment in a dependable grinder contributes article source considerably to improved income and competitiveness in the coffee market.

In the competitive landscape of coffee production, choosing the best industrial coffee mill plays a pivotal function in improving both effectiveness and product quality. The 2 key types of grinders are blade grinders and burr mills. Within the burr grinder classification, there are flat burr grinders and conical burr grinders, each with its benefits. Burr grinders are typically preferred over blade mills, as they supply a consistent work dimension, which is important for optimal removal and flavor.

In summary, a commercial coffee grinder plays a pivotal duty in enhancing both efficiency and item quality within coffee manufacturing.

Comments on “Industrial Coffee Grinder vs. Personal Grinder: Main Differences Detailed”